Description

Madre Tierra Sugar mill required the necessary conditions to increase grinding capacity from 10,500 to 14,000 tons per day. After ten years of collaboration with ABS and with its brands ACB and AEC, the grinding requirement was met, perpetuating our history of generating the best solutions, which include:

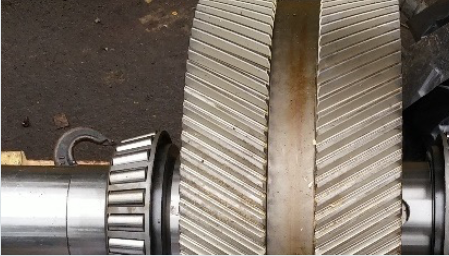

- Production of open transmissions with straight tooth ends can handle 1500 hp of engine power.

- 12 split bearing brackets for the sprockets of open transmissions with 17″ shafts, resulting in improved load transmission.

- Repowering intermediate reducers of Philadelphia brand mills from 1650 Hp to 3375 Hp using ABS-MGS reverse engineering.

- In the first intermediate elevator, a switch from rivet-less chains to contamination-free chains with sprocket system hardness segments ranging from 45 to 55 HRC.

- Use a UPS mid-control shaft installation is explicitly designed for use with high-capacity spherical bearings.

We will continue to collaborate with customers through our local presence to provide immediate assistance for the collaborative creation of successful projects for the sugar industry’s future.