The customer

The Case

Technical Solution

How does a rotary clay dryer mill work?

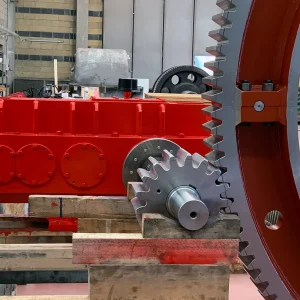

Rotary dryers are a very effective industrial drying option for bulk solids. They are often chosen for their robust processing capacity and versatility to operate optimally regardless of the raw material.

Rotary dryers operate by spinning the material in a rotating drum while conveying a drying air stream. Depending on the model, they can also be indirectly heated to avoid direct contact with the material.

The drum is placed on a slight horizontal slope to allow gravity to help move the material through the drum. As the drum rotates, lifting vanes pick up the material and drop it through the air stream to make heat transfer more efficient and consequently drying. When working with agglomerates, the rotation also allows, as an added benefit, further smoothing and polishing of the granules.

MGS GEARS, Technical Excellence for the Heavy Industry

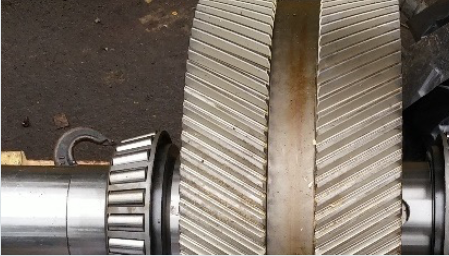

For over 20 years, we have been offering products and engineering solutions for all types of industrial applications drives such as Ball Mills, Rotary Dryer Furnaces, Bucket Elevators, using gearboxes and components capable of adapting to any assembly requirement, space availability, and required torque and ratio, etc. We count on a wide range of special bearings and power transmission solutions for the CEMENT industry to help optimize your production processes and extend the life of your industrial equipment.”

Rotary dryers operate by spinning the material in a rotating drum while conveying a drying air stream. Depending on the model, they can also be indirectly heated to avoid direct contact with the material.

The drum is placed on a slight horizontal slope to allow gravity to help move the material through the drum. As the drum rotates, lifting vanes pick up the material and drop it through the air stream to make heat transfer more efficient and consequently drying. When working with agglomerates, the rotation also allows, as an added benefit, further smoothing and polishing of the granules.